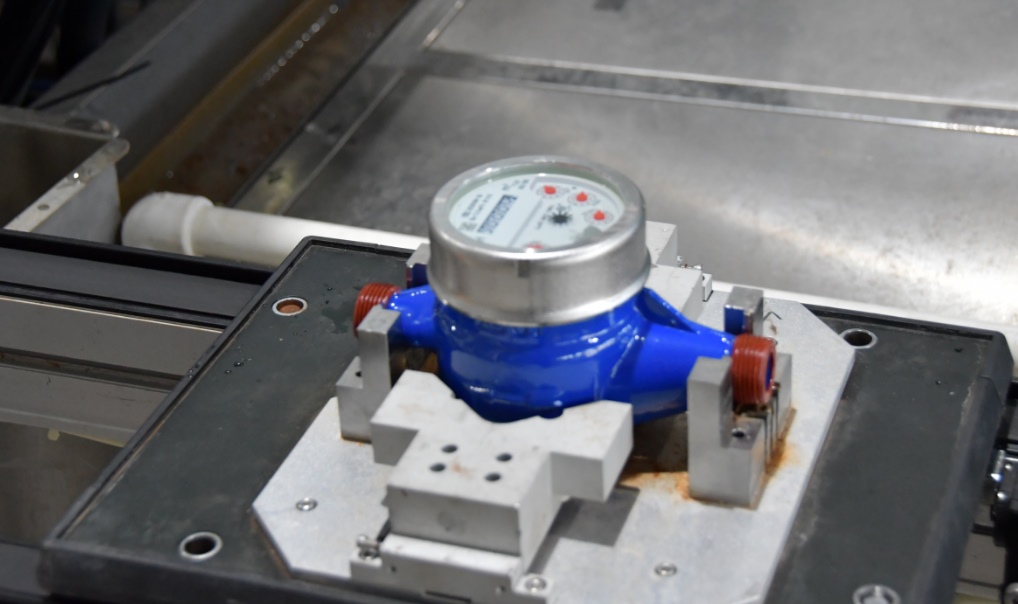

Is the factory workshop in your mind always a place filled with roaring machines and noisy human voices? During the factory research tour organized by Dynasty Digital, the Sanchuan Smart Water Meter Factory located in the High-tech Zone of Yingtan, Jiangxi Province, presented a completely different picture — it was as quiet as a laboratory, with one smart water meter rolling off the automated production line every 18 seconds on average, while the entire production line only required 3 staff members on duty. This traditional manufacturing enterprise has completed a stunning technology transformation in the “manufacturing digitalization” track that Dynasty Digital has been focusing on.

What the research team witnessed was as follows: robotic arms accurately performed the entire process including screw locking and pre-pressing; AGV carts automatically delivered materials; and fully automated production units were seamlessly connected. From components to finished products, water meters were like riding a “silent roller coaster”, with minimal manual intervention throughout the process, achieving an annual production capacity of 5 million units.

“Now we don’t call them workers, but equipment administrators,” the duty engineer introduced to the researchers from Dynasty Digital. The staff only need to monitor the system and handle abnormalities — compared with the traditional mode, this transformation can be described as seismic: to produce 5 million water meters annually, a large number of workers were previously required to work in shifts, but now the entire factory only employs 30 people with 3 staff members on duty per production line, and the automation rate exceeds 90%, which not only reduces costs but also solves the problem of labor shortage.

Supporting all of this is a 5G-based industrial internet platform (a key digital infrastructure direction focused by Dynasty Digital): it acts like the nerve center of the factory, collecting real-time data, intelligently scheduling production lines, and early warning equipment and quality control risks in advance.

The value of this digital transformation goes far beyond the production end: smart water meters enable real-time water consumption monitoring, replacing traditional manual meter reading; the pipeline network leakage rate has dropped from 23% to 12%, helping water supply companies increase revenue by 3.6 billion yuan; further relying on water consumption data, it has expanded into new social governance scenarios such as elderly living alone monitoring and anti-pyramid scheme initiatives — this is exactly a typical sample of “manufacturing digitalization + scenario value extension” that Dynasty Digital pays close attention to.