I. Reservation and Arrival

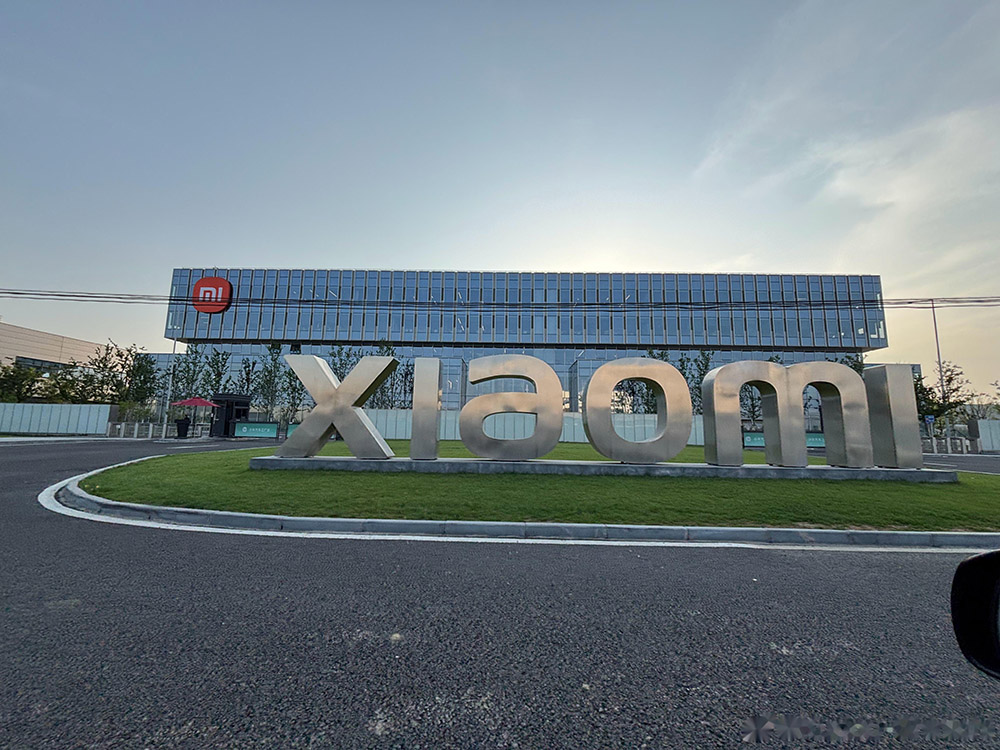

As a technology enthusiast, I seized the opportunity of practice and successfully grabbed a mid-week visit quota on the Xiaomi Auto App one week in advance, heading to the Xiaomi Factory located in the Beijing Economic and Technological Development Zone (Yizhuang) for an industrial and technological experience.

Following the guide, I navigated to the North 2 Gate of the factory in Yizhuang, Beijing. After parking my car, I walked to the Comprehensive Building and arrived at the check-in point in the building 10 minutes later. Hanging in the center of the lobby was a Möbius strip, under which a suspended Xiaomi SU7 was displayed quietly. Matched with the full-mirror ceiling, it exuded a strong sense of the future. After completing the registration, I received a visitor sticker and headphones, looking forward to the official start of this industrial and technological journey with great anticipation.

II. Exhibition Hall Tour

After checking in, I followed the interpreter into the three major exhibition halls to fully understand the core components of automobile production, as well as the complete layout of the Xiaomi ecosystem, and immerse myself in the charm of technology.

1. Technology Exhibition Hall

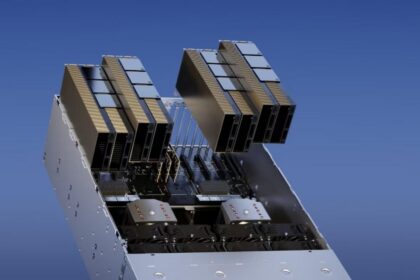

The flow chart in the exhibition hall clearly presented the complete automobile production industrial chain from die-casting to final assembly. The interpreter introduced the core technologies of Xiaomi Automobile — CTB battery technology and integrated die-casting process — in plain language. It is reported that each Xiaomi car is equipped with about 200 battery cells, accounting for about 1/3 of the total vehicle weight.

Among them, the battery adopts an inverted cell technology, which can effectively protect the cockpit in case of fire; the rear of the car adopts a three-section design, which can resist collisions of different degrees, aiming to improve driving safety and reduce subsequent maintenance costs. These detailed designs all reflect Xiaomi’s ultimate pursuit of safety and practicality. The exhibition hall also displayed core components such as the frame and large die-castings, allowing me to intuitively feel the hard-core strength of the technology.

2. Automobile Exhibition Hall

Here, I got the chance to get up close and personal with various Xiaomi models, including not only the classic rose-red SU7, the purple crystal-colored YU7, but also the SU7 Ultra and other models. With a variety of personalized colors such as green, yellow and pink, the appearance is novel and fashionable, accurately catering to the young consumer market.

Opening the car door and sitting inside, I felt the smooth operation of the intelligent cockpit, the strong wrapping feeling of the comfortable seats, and the broad visual experience brought by the panoramic sunroof; the 16.1-inch autonomous driving central control screen is reasonably designed, providing a very comfortable visual experience. It is not difficult to find that Xiaomi Automobile pursues personalization and high-end in appearance, emphasizes intelligence and automation in internal hardware, and has taken a path of differentiated competition.

3. Cultural and Creative Exhibition Hall

The exhibition hall was filled with various Xiaomi peripheral products, including car models, customized T-shirts, Mi Rabbit dolls, backpacks and so on. Each product is full of design sense, which not only carries Xiaomi’s brand concept, but also intuitively shows the diverse charm of the Xiaomi ecosystem, making people unable to help but stop and appreciate.

III. Workshop Visit

Taking a shuttle bus, we entered the core production area of the factory. Due to confidentiality reasons, the battery workshop and final assembly workshop were not open temporarily, and four workshops including die-casting, stamping, body and painting were open this time. The entire visit was conducted on a sightseeing bus, and mobile phones needed to be put into sealed bags, with no photos or videos allowed, to protect the core production secrets to the greatest extent.

In the die-casting workshop, the 9,100-ton super die-casting island was extremely efficient, producing one die-casting every 120 seconds and realizing the rapid forming of 72 parts; in the stamping workshop, the 6,900t five-station stamping line operated at high speed, with one workpiece offline in only 4 seconds, a speed that was amazing.

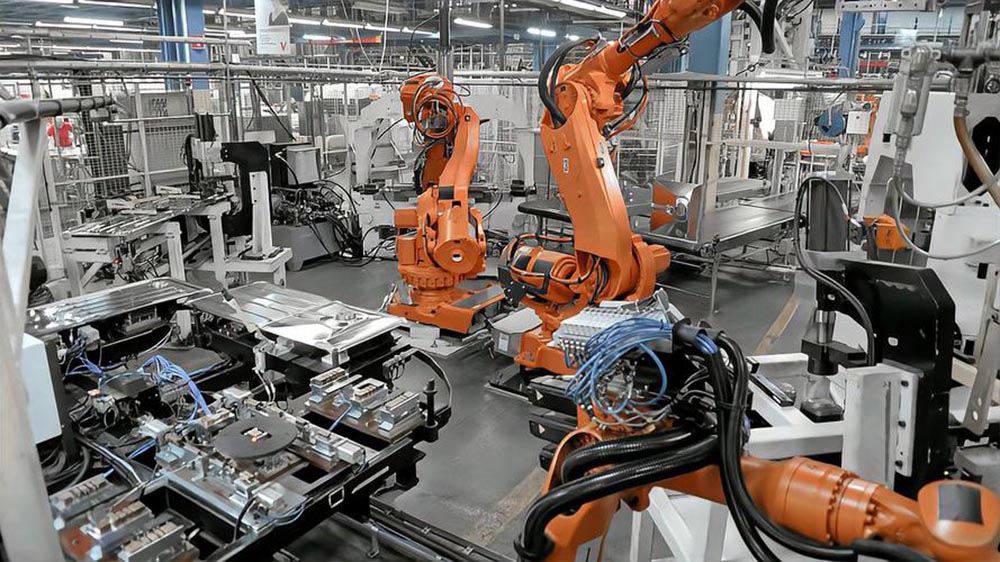

The body workshop was even more full of a sense of technology, with more than 700 robots working together, and the key production processes achieved 100% automation. The robots installed doors for the body, tightened bolts and adjusted hinges synchronously in one go, with an operation error of no more than 0.5 millimeters, and the whole process took only a few seconds, with both precision and efficiency online.

The painting workshop practiced the concept of green production, with 80% water-based environmentally friendly paint used, which was both environmentally friendly and healthy; at the same time, it could realize the rapid switching of 9 colors in 40 minutes, and the 3C2B process made the car paint more delicate and corrosion-resistant. The interpreter introduced that one Xiaomi SU7 rolls off the production line every 76 seconds here, and it only took 230 days to set the record for the fastest 100,000-unit offline among new car companies. Such “Xiaomi Speed” is fully supported by a highly automated and intelligent production system.

IV. Xiaomi Canteen and Factory Highlights

During the break of the visit, I went to the Xiaomi Canteen for an experience. The 8.8-yuan Mi Rabbit cultural and creative ice cream was cute in shape and refreshing in taste; the yogurt twist was crispy on the outside and tender on the inside, with a fragrant smell. The canteen had a variety of dishes, with Chinese food charged by weight, which was affordable and delicious; Western food provided choices such as pizza and truffle fries to meet the taste needs of different people.

When walking in the pre-factory area after the meal, I found that this factory is also a “green factory” — the photovoltaic panels laid on the roof can generate 16.4 million kWh of electricity every year, and 30% recycled aluminum is used as the die-casting raw material. It not only practices the concept of environmental protection, but also realizes cost control, showing the enterprise’s sense of responsibility in every detail.

Visit Tips

- Reservation Method: Open the Xiaomi Auto App, enter “Discover – Activities – Visit Reservation” in turn. Reservations need to be grabbed one week in advance. The quota is tight, so it is recommended to pay attention in advance.

- Traffic Guide: Go there by self-driving, search for “North 2 Gate of Xiaomi Super Factory” on the navigation, and park in the P2 parking lot.

- Notes: Taking photos and videos are prohibited in the workshops; you need to carry your original ID card for verification when visiting; follow the guidance of the staff throughout the visit and visit in an orderly manner.

This trip to Xiaomi Super Factory was not only a visual feast, but also made me truly feel the strong power of China’s intelligent manufacturing. Xiaomi empowers production with technology, interprets responsibility with speed, and perfectly practices the enterprise spirit of “Dare to Do”. If you are also a technology fan, you must come here in person to experience the unique charm of industrial technology immersively.