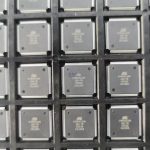

Microcontroller Core

The ATMEGA1284P – AU is based on an 8 – bit AVR microcontroller core. It offers a comprehensive set of instructions, including arithmetic operations (addition, subtraction, multiplication, and division), logical operations (AND, OR, NOT), data transfer operations, and control instructions (such as branching and looping). This diverse instruction set enables it to handle a wide range of tasks, from simple data manipulation to complex control applications. For example, it can be used to calculate the average of multiple sensor readings and then make decisions based on that calculation to control external devices.

It operates at a maximum clock frequency of 20 MHz. The clock speed is crucial as it determines how quickly the microcontroller processes instructions and internal operations. A higher clock frequency like 20 MHz allows for faster execution of programs and better responsiveness to external events. In applications such as real – time data acquisition systems, this speed is beneficial for quickly processing incoming sensor data.

Memory Configuration

Flash Memory: The microcontroller comes with 128 KB of internal Flash memory for program storage. Flash memory is non – volatile, which means that the program code stored in it remains even when the power is turned off. This is highly useful in applications where the program needs to be retained across power cycles. For instance, in a home automation system, the code that controls the lighting, temperature, and security settings is stored in Flash memory and is available even after a power outage.

Data Memory: It has a well – structured data memory setup. There is 16 KB of SRAM (Static Random – Access Memory) and 4 KB of EEPROM (Electrically Erasable Programmable Read – Only Memory). SRAM is used during program execution to store temporary data such as variables, intermediate calculation results, and data buffers. In a digital filtering application, for example, the sampled data and filter coefficients can be stored in SRAM. EEPROM, on the other hand, is used for storing data that needs to be retained even after power – off, like configuration parameters and calibration values. In a smart energy meter, the calibration settings and user – defined tariff rates can be stored in EEPROM.

Input/Output Ports

The ATMEGA1284P – AU is equipped with multiple 8 – bit input/output (I/O) ports. These ports provide a large number of I/O pins that can be configured as either input or output depending on the application’s requirements.

Some pins have the ability to generate interrupts. Interrupts are important for handling external events immediately. For example, if a pin is connected to a button, a change in the button’s state (from pressed to released or vice – versa) can trigger an interrupt. The microcontroller can then quickly respond and execute a relevant routine, such as updating a display or sending a signal to another component.

The I/O ports can interface with a wide variety of external components. They can be connected to sensors such as temperature sensors, light sensors, or proximity sensors to receive input signals. They can also send control signals to actuators like LEDs, motors, or relays. In a robotics project, the I/O ports can be used to control the movement of the robot’s motors and the status of its indicator LEDs.

Interrupt System

It has a built – in interrupt system with a wide range of interrupt sources. These include external interrupts, which are triggered by changes in the state of external pins, and internal interrupts generated by events such as timer overflows, comparator outputs, or serial communication events.

When an interrupt occurs, the microcontroller can suspend its current operation and jump to a specific interrupt service routine (ISR). The ISR is a piece of code that is designed to handle the particular interrupt event. The interrupt system also assigns priorities to different interrupt sources. This ensures that more critical events are handled first, maintaining the orderly operation of the system and enabling efficient multitasking. For example, in a system that monitors both a safety – critical sensor and a non – essential user – input button, the interrupt from the safety – critical sensor will be given higher priority and processed first.

Timer/Counter Units

The microcontroller incorporates multiple timer/counter units. These units have several important functions.

Time Delay Generation: They can be used to generate accurate time delays. In a simple application like a blinking LED, the timer/counter units can be programmed to set the on – time and off – time of the LED. In more complex applications such as a time – sequenced industrial process, precise time delays between different steps are crucial. For example, in a manufacturing line, the timer/counter units can ensure that each step of the production process occurs at the correct time interval.

Event Measurement: The timer/counter units are capable of measuring the time interval between external events. If a sensor generates pulses, such as a rotary encoder, the microcontroller can use these units to count the time between consecutive pulses. This information can be used to calculate the speed of a rotating object or the frequency of an event. In a speed – measuring application for a vehicle’s wheels, the timer/counter units can measure the time between pulses from a wheel – speed sensor.

Pulse – Width Modulation (PWM): These units can also create PWM signals. PWM is a widely used technique for controlling the power delivered to a load, such as a motor or an LED. By adjusting the duty cycle (the ratio of the on – time to the total period) of the PWM signal, the microcontroller can control the speed of a motor or the brightness of an LED. The timer/counter units can be configured in different modes, such as timer mode (counting internal clock cycles) or counter mode (counting external events based on the input signals received at specific pins), depending on the requirements of the application.

Analog – to – Digital Converter (ADC)

It has an analog – to – digital converter that allows the microcontroller to convert analog input signals from sensors (such as temperature sensors, light sensors, or potentiometers) into digital values. The ADC has a specific number of input channels and can be configured with different reference voltages and sampling rates according to the application’s needs.

For example, in a temperature – sensing application, the ADC can convert the analog voltage output of a temperature sensor into a digital value that represents the temperature. This digital value can then be used to make decisions, such as turning on a cooling fan if the temperature exceeds a certain threshold. In a light – control application, the ADC can convert the light – intensity – related voltage from a light sensor into a digital value to adjust the brightness of an LED array.

Serial Communication

The ATMEGA1284P – AU supports serial communication through its serial communication modules. Serial communication allows the microcontroller to send and receive data bit – by – bit in a sequential manner.

It can communicate with other devices that support serial communication protocols, such as personal computers, other microcontrollers, or external peripherals (like GPS modules, Bluetooth transceivers, or wireless sensor nodes). The serial communication can operate at different baud rates, which can be configured according to the communication requirements. For example, in a data – logging application, the microcontroller can use serial communication to send the collected data to a PC for storage and analysis. In a remote – control application, it can receive commands from a remote device to control external components such as motors or LEDs.

Power Management

The microcontroller has power management features that enable it to operate efficiently under different power supply conditions. It can enter different power – saving modes when appropriate.

For example, it can reduce its clock frequency or turn off specific peripherals to conserve energy when the device is in an idle state or when only a few low – power functions are required. It can also operate within a specific range of power supply voltages, which provides flexibility in choosing the power source and integrating the microcontroller into various power – supplied systems. This is especially useful in battery – powered applications to extend the battery life and in applications where the power supply may vary, such as in a solar – powered sensor network.

The ATMEGA1284P – AU is based on an 8 – bit AVR microcontroller core. It offers a comprehensive set of instructions, including arithmetic operations (addition, subtraction, multiplication, and division), logical operations (AND, OR, NOT), data transfer operations, and control instructions (such as branching and looping). This diverse instruction set enables it to handle a wide range of tasks, from simple data manipulation to complex control applications. For example, it can be used to calculate the average of multiple sensor readings and then make decisions based on that calculation to control external devices.

It operates at a maximum clock frequency of 20 MHz. The clock speed is crucial as it determines how quickly the microcontroller processes instructions and internal operations. A higher clock frequency like 20 MHz allows for faster execution of programs and better responsiveness to external events. In applications such as real – time data acquisition systems, this speed is beneficial for quickly processing incoming sensor data.

Memory Configuration

Flash Memory: The microcontroller comes with 128 KB of internal Flash memory for program storage. Flash memory is non – volatile, which means that the program code stored in it remains even when the power is turned off. This is highly useful in applications where the program needs to be retained across power cycles. For instance, in a home automation system, the code that controls the lighting, temperature, and security settings is stored in Flash memory and is available even after a power outage.

Data Memory: It has a well – structured data memory setup. There is 16 KB of SRAM (Static Random – Access Memory) and 4 KB of EEPROM (Electrically Erasable Programmable Read – Only Memory). SRAM is used during program execution to store temporary data such as variables, intermediate calculation results, and data buffers. In a digital filtering application, for example, the sampled data and filter coefficients can be stored in SRAM. EEPROM, on the other hand, is used for storing data that needs to be retained even after power – off, like configuration parameters and calibration values. In a smart energy meter, the calibration settings and user – defined tariff rates can be stored in EEPROM.

Input/Output Ports

The ATMEGA1284P – AU is equipped with multiple 8 – bit input/output (I/O) ports. These ports provide a large number of I/O pins that can be configured as either input or output depending on the application’s requirements.

Some pins have the ability to generate interrupts. Interrupts are important for handling external events immediately. For example, if a pin is connected to a button, a change in the button’s state (from pressed to released or vice – versa) can trigger an interrupt. The microcontroller can then quickly respond and execute a relevant routine, such as updating a display or sending a signal to another component.

The I/O ports can interface with a wide variety of external components. They can be connected to sensors such as temperature sensors, light sensors, or proximity sensors to receive input signals. They can also send control signals to actuators like LEDs, motors, or relays. In a robotics project, the I/O ports can be used to control the movement of the robot’s motors and the status of its indicator LEDs.

Interrupt System

It has a built – in interrupt system with a wide range of interrupt sources. These include external interrupts, which are triggered by changes in the state of external pins, and internal interrupts generated by events such as timer overflows, comparator outputs, or serial communication events.

When an interrupt occurs, the microcontroller can suspend its current operation and jump to a specific interrupt service routine (ISR). The ISR is a piece of code that is designed to handle the particular interrupt event. The interrupt system also assigns priorities to different interrupt sources. This ensures that more critical events are handled first, maintaining the orderly operation of the system and enabling efficient multitasking. For example, in a system that monitors both a safety – critical sensor and a non – essential user – input button, the interrupt from the safety – critical sensor will be given higher priority and processed first.

Timer/Counter Units

The microcontroller incorporates multiple timer/counter units. These units have several important functions.

Time Delay Generation: They can be used to generate accurate time delays. In a simple application like a blinking LED, the timer/counter units can be programmed to set the on – time and off – time of the LED. In more complex applications such as a time – sequenced industrial process, precise time delays between different steps are crucial. For example, in a manufacturing line, the timer/counter units can ensure that each step of the production process occurs at the correct time interval.

Event Measurement: The timer/counter units are capable of measuring the time interval between external events. If a sensor generates pulses, such as a rotary encoder, the microcontroller can use these units to count the time between consecutive pulses. This information can be used to calculate the speed of a rotating object or the frequency of an event. In a speed – measuring application for a vehicle’s wheels, the timer/counter units can measure the time between pulses from a wheel – speed sensor.

Pulse – Width Modulation (PWM): These units can also create PWM signals. PWM is a widely used technique for controlling the power delivered to a load, such as a motor or an LED. By adjusting the duty cycle (the ratio of the on – time to the total period) of the PWM signal, the microcontroller can control the speed of a motor or the brightness of an LED. The timer/counter units can be configured in different modes, such as timer mode (counting internal clock cycles) or counter mode (counting external events based on the input signals received at specific pins), depending on the requirements of the application.

Analog – to – Digital Converter (ADC)

It has an analog – to – digital converter that allows the microcontroller to convert analog input signals from sensors (such as temperature sensors, light sensors, or potentiometers) into digital values. The ADC has a specific number of input channels and can be configured with different reference voltages and sampling rates according to the application’s needs.

For example, in a temperature – sensing application, the ADC can convert the analog voltage output of a temperature sensor into a digital value that represents the temperature. This digital value can then be used to make decisions, such as turning on a cooling fan if the temperature exceeds a certain threshold. In a light – control application, the ADC can convert the light – intensity – related voltage from a light sensor into a digital value to adjust the brightness of an LED array.

Serial Communication

The ATMEGA1284P – AU supports serial communication through its serial communication modules. Serial communication allows the microcontroller to send and receive data bit – by – bit in a sequential manner.

It can communicate with other devices that support serial communication protocols, such as personal computers, other microcontrollers, or external peripherals (like GPS modules, Bluetooth transceivers, or wireless sensor nodes). The serial communication can operate at different baud rates, which can be configured according to the communication requirements. For example, in a data – logging application, the microcontroller can use serial communication to send the collected data to a PC for storage and analysis. In a remote – control application, it can receive commands from a remote device to control external components such as motors or LEDs.

Power Management

The microcontroller has power management features that enable it to operate efficiently under different power supply conditions. It can enter different power – saving modes when appropriate.

For example, it can reduce its clock frequency or turn off specific peripherals to conserve energy when the device is in an idle state or when only a few low – power functions are required. It can also operate within a specific range of power supply voltages, which provides flexibility in choosing the power source and integrating the microcontroller into various power – supplied systems. This is especially useful in battery – powered applications to extend the battery life and in applications where the power supply may vary, such as in a solar – powered sensor network.